MBS Screw presses

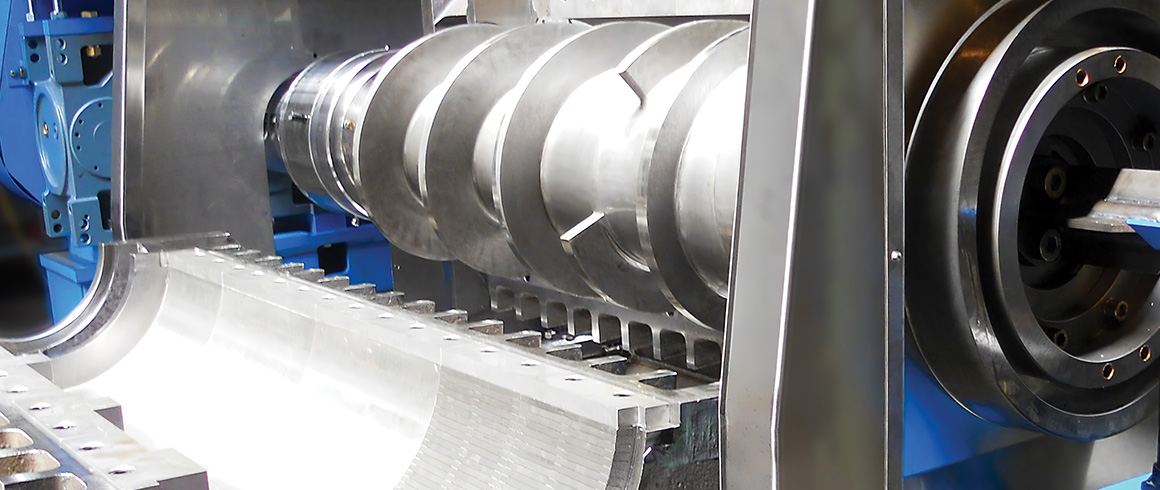

OLEXA® has a unique expertise in the field of separation of solid/liquid phases by means of continuous pressure. The screw press is mainly composed of:

- A control group comprising an electric motor and a reducer.

- A rigid frame which makes up the chassis of the press, and the tray which receives the pressed juice.

- Two half cages which are cast or fabricated with welded or stainless steel

- The cage consists of perforated plates or bars with geometrical characteristics which are adapted to the performance of the machine.

- A piece or central shaft assembly with screws and rings

- A thrust housing.

- A fixed or removable stopper with hydraulic or pneumatic cylinder

- A protective casing for the entire machine in either stainless or painted steel.

Specially adapted to the challenges of dewatering

Strong points

- Simplicity of operation

- Continuous production concerning dewatering

- High rate of dewatering

- Robust construction and adapted to the products being handled

- Low maintenance overhead

- Continuous production 24/7 without the need for human surveillance

options

- Manufactured in heat-treated or stainless steel

- Welded steel cage for the treatment of low pressure products

- Moulded cage for the treatment of high pressure products

- Cage with treated bars, perforated sheets or other specific production

- Appropriate treatment of the screw press against wear & tear...